marine rubber fender

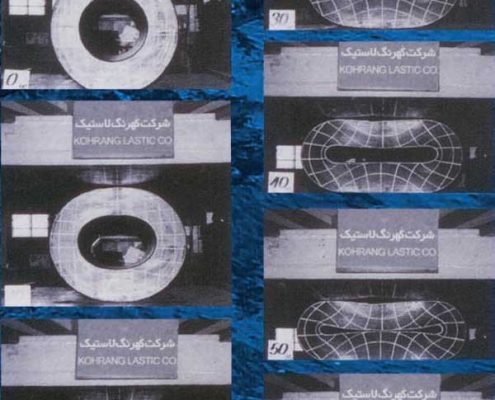

1 – KOHRANG Shock cell:

Shock cell are a type of marine fender that is used in the naval navigation system on the offshore platforms. The structure of these components is made up of two concentric metal pipes and rubber in between , which they act as the energy absorption system during the propulsion of floaters on oil rigs.

The moorings of ships at the offshore platforms varies substantially from the coastal harboring systems.

The elastic characteristic of rubber in the Shock cell causes the absorption of the resulting kinetic energy and reduces the reaction forces. This reduces the primary force exerted during docking and thus prevents the chance of damage to the ship or the dock due to the reaction force.

The high level of force excreted on the Shock cell, as well as the sensitive position of it between the offshore platform and the vessels are strong reasons for producing this piece with utmost sensitivity accuracy. The most important aspect of achieving high quality are the proper bonding of rubber and the metal parts, the Formula used to make the rubber and also the type of metal used.

At the present time, Kohrang Lastic Co., based on the technical knowledge of its experts, has the ability to produce Shock cell and other equipment for mooring systems in offshore areas. This company has manufactured and supplied Shock cell to most projects in Iran including the production of phases 13-18,19 / 17-19 ,20,21,22- 24 and B19of South Pars(Pars-e-Jonoubi) , Farzad and Froozan projects

2-KOHRANG Cylindrical Fender:

Cylindrical fenders are one of the oldest and most versatile type of marine fenders that can be used in a variety of docks with different applications .The ratio of the energy absorption to reaction force is less than the other fenders, but their special simple form of installation makethem very desirable . The cylindrical fenders, as its name implies, are cylindrical and installed with chains, belts or brackets on the face of the quay.

Cylindrical fenders are very popular in all ports of Iran due to the fact that they are very economical and easy to install.

Cylindrical fenders manufactured by Kohrang Lastic Co. are made according to the current international standards and can be designed and produced according to specific orders.

3-KOHRANG Cell Fender:

Cell fenders are currently the most popular type of fender that are used all over the world. Undoubtedly, the most important factor in the popularity of this type of fender is the ability to absorb maximum amount of energy and the wide range in size and capacity. In addition, the three-dimensional dilatation of this type of fender with its elasticity compared to other types of fenders distinguishes it. Cell fenders are a combination of rubber and steel. Steel plates are placed in the fender body and coated with rubber and vulcanization occurs in the mold while applying heat at specific temperature and pressure. This combination strengthens the fender body and thus enables it to withstand predefined vertical and horizontal pressures. These fenders are fitted with bolt, chains, and brackets and on the wall of the berth. Generally a frontal frame is installed On the fender face and the size of the frontal frame is in accordance to the location and type of use.

The most common use of cell fenders is in cargo ports, because its high energy absorption capacity along with the structure of these fenders allows for the installation and operation in various docks from 50,000 to 500,000 tons. The main features of this type of fender are:

- High energy absorption versus low reaction force

- Able to distribute forces in the frontal frame

- Allows the docking of ships at an angle

- Variation in load capacities

- Variation in behavior by changing the type of comp and

4-KOHRANG D-Fenders:

D-shaped fenders are available in DO and DD forms, which are very common in a variety of docks. The installation of these fenders is very easy and can be installed on the wall of the docking port or the body of floating vessel using chains, belt and bolts. Smaller D-shaped fender is often fixed on the body of floating vessels.

Some of the most important features of D-shaped fender is as listed below:

- Lower reaction force and more energy absorption compared to cylindrical fender

- Ease of installation

- Ability to be fixed on the bodies of vessels and ships due to small width.

5-KOHRANG V shaped fender or KOHRANG Arch Fender:

The v-shaped rubber fender; which the most common type of that in Iran is the “Super Arch Fender” due to its superb performance are one of the most commonly used fenders in Iran and also in the rest of the world.

Based on the condition of various docks and depending on the specific requirement of use, can be equipped with Polyethylene pad and frontal frames. The variety of sizes and shapes gives the flexibility to the consulting engineers to have the best choice from these types of fender. The installation of v-shaped fenders is done by bolt and nuts, and can be installed vertical, horizontal, or even diagonal for the intended purpose of the users.

The most prominent features of the v-shaped fenders are:

- High energy absorption and low reaction force

- High durability

- Extensive scope in terms of size and energy absorption

- Ease of installation

- Suitable for maximum energy absorption

6-KOHRANG Shear fender:

Shear fender is used to absorb energy during mooring, in order to protect the ship and the berth from damage. The shear fender is unique due to its characteristic that proportional to the exerted load, linear deformation occurs. These fenders are easy to install and are suitable for low energy absorption. The steel plates used in these fenders are completely covered with rubber and thus prevent the corrosion of the plates and minimizes the maintenance costs

7-KOHRANG Cone fender:

These fenders are the latest generation of cell rubber fender. The conical shape has enabled the fender to withstand a combination of axial, shear, and angular loading, which makes this type of fender ideal where heavy blows and wide angle moorings are done. These fenders are made in such a way that their excessive density is prevented. This feature of the cone fender completely protects it from accidental damages.