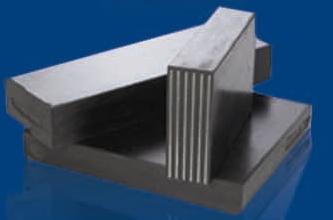

Bridge shock absorbers(Neoprene )

Mechanical forces including horizontal, vertical and torsional loads on a bridge bearing in combination with stresses due to contraction and expansion and creep of the materials cause changes in shape and create complex movements in the structure of ridges. In order to control these movements and ensure that it does not lead to a change in shape and unwanted stresses, specific type fenders are placed under the column of the bridge bearing called Neoprene . This product Is made o sheets of metal arranged within the rubber and vulcanized together.

Neoprene at Kohrang Lastic co.; based on the given specification in terms of loads and various applications, are designed and manufactured in accordance with ASTM D4014 and DIN4141, BS EN 1337 standards. The neoprene produced by this company are highly resistant to severe working condition and the sun’s rays.